Hazard Analysis Critical Control Point (HACCP)

Hazard Analysis Critic Control Point (HACCP) is an internationally accepted, formal and documented food safety management system. It focuses on the prevention of food safety problems before they occur and is the most effective means of controlling food pathogens. This guide is based upon the seven HACCP principles and the way HACCP works is very similar to other risk assessments and risk management processes you may be familiar with, for example fire safety. They should, of course, form part of your essential staff training package.

There are seven principles of HACCP:

- Conduct a hazard analysis

- Determine the critical control points (CCP)

- Establish critical limits

- Establish monitoring procedure to control the CCPs

- Establish corrective action when monitoring indicates the CCP is not controlled

- Put in place procedures for verification/confirm that the HACCP is working effectively

- Retain documentation for all procedures and records

Pre Requisite Programmes (PRP)

These are systems that should be in place before HACCP is even considered. They include:

- pest control

- cleaning routines

- maintenance

- personal hygiene

- supplier quality assurance

- staff training.

There’s precious little point in producing a HACCP plan if the underlying basics aren’t in place. As a registered food premises and professional operator you will have implemented policies for each PRP so it’s clear how you manage the general hazards of your food business. The advantage of PRPs is that they allow you to focus your attention on the more significant hazards during HACCP.

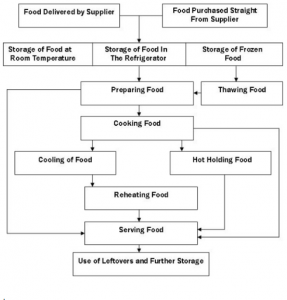

Produce a Flow Chart

The production of a flow chart that outlines all the process steps in your food operation is possibly the most important part of HACCP in the early stages. Keeping an accurate and up to date process flow chart will ensure that every aspect of your operation will be assessed in your HACCP plan. If your HACCP plans do not cover all parts of the process, then your HACCP is invalid. Once your flow chart is complete, you need to confirm that it is accurate by checking it off against what actually happens. Occasionally freezing down product before it goes out of date may make sound financial sense but is it covered in your flow chart/HACCP plan?

For instance this is a very basic flow chart for a food business:

You might want to produce separate flowcharts that detail the individual areas such as one on correct thawing or reheating food as well.

Continue reading … page 2